Unleashing the Power of Calcium Carbonate in the PVC Industry

- Ashutosh Khandelwal

- Sep 16, 2024

- 2 min read

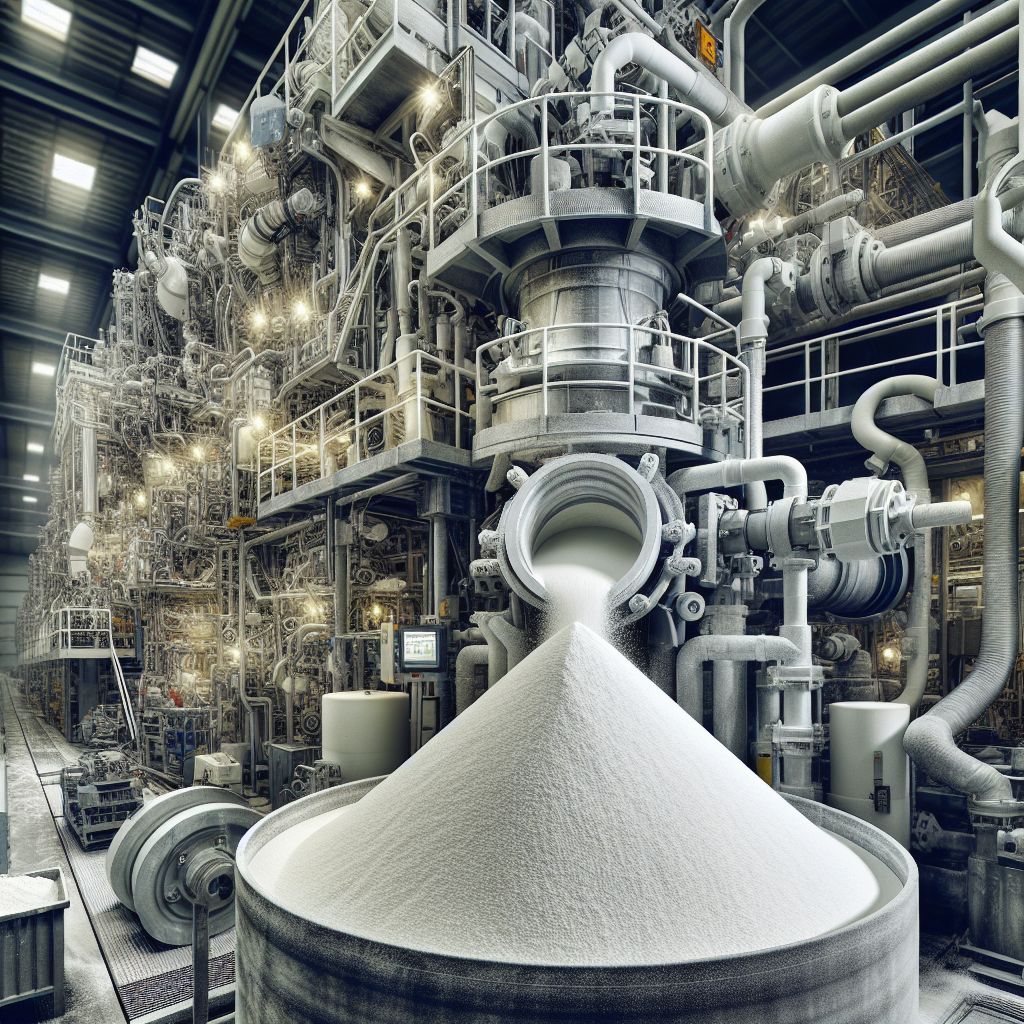

In the realm of the PVC industry, where innovation and quality reign supreme, one crucial ingredient stands out among the rest – calcium carbonate. Found naturally in rocks and minerals, this versatile compound plays a significant role in enhancing the properties of PVC products. Let's delve into the captivating world of calcium carbonate and uncover why it is a game-changer in the PVC sector.

Understanding the Essence of Calcium Carbonate

Calcium carbonate , derived from various sources such as Vietnam, Egypt, and Malaysia, serves as a key additive in the PVC manufacturing process. Its ability to enhance strength , durability , and surface finish makes it a popular choice among manufacturers seeking to elevate the quality of their products.

Fortifying PVC Resin with Calcium Carbonate

When calcium carbonate is integrated into PVC resin, the resulting compound exhibits improved impact resistance and thermal stability . This fortification not only enhances the overall mechanical properties of PVC products but also prolongs their lifespan , making them a sustainable choice for various applications.

Aesthetics Enhanced with Titanium Dioxide

In conjunction with calcium carbonate, the inclusion of Titanium Dioxide in PVC formulations further enhances the aesthetic appeal of products. This combination offers superior opacity and UV resistance , ensuring that PVC items maintain their color vibrancy and structural integrity over time.

Sustainability and Cost-Effectiveness

Beyond its performance benefits, calcium carbonate presents a compelling case for sustainability and cost-effectiveness in PVC production. As a naturally abundant mineral, it offers a renewable and environmentally friendly alternative to synthetic additives. Moreover, its affordability makes it an attractive option for manufacturers looking to optimize their production processes without compromising on quality.

The Versatility of Calcium Carbonate in PVC Applications

From pipes and fittings to siding and windows , calcium carbonate finds its way into a myriad of PVC applications. Its versatility allows for the creation of products that excel in both structural integrity and aesthetic appeal , catering to the diverse needs of industries ranging from construction to healthcare.

Harnessing the Potential of Calcium Carbonate in Delhi and Beyond

In regions like Delhi, where the demand for high-quality PVC products is on the rise, the strategic utilization of calcium carbonate is paramount. By sourcing top-grade calcium carbonate in Delhi and leveraging its benefits in PVC production, manufacturers can stay ahead of the competition and meet the evolving needs of consumers.

Embracing Innovation and Quality with Calcium Carbonate

As the PVC industry continues to evolve, the role of calcium carbonate remains indispensable. Its unique blend of performance-enhancing and cost-effective properties makes it a cornerstone of modern PVC manufacturing. By embracing the innovative possibilities offered by calcium carbonate, manufacturers can unlock new horizons of quality, sustainability, and excellence in their products.

In conclusion, the integration of calcium carbonate in the PVC industry represents a paradigm shift towards efficiency , sustainability , and innovation . With its remarkable properties and diverse applications, calcium carbonate emerges as a catalyst for driving the industry towards a brighter and more prosperous future.

So, the next time you encounter a PVC product that impresses with its durability and aesthetic allure, remember the unsung hero that makes it all possible – calcium carbonate.

SEO Keywords: calcium carbonate in delhi, Vietnam Calcium Carbonate, egypt calcium carbonate, PVC resin in delhi, Titanium Dioxide in delhi

Comments